Beauty products and makeup brands are well-known for their appearance, hygiene, and packaging. The sales and profits of makeup are primarily dependent upon their successful packaging. The type of material a firm pick as packaging material dramatically impacts the customer’s mind.

Packaging materials and packaging technology are advancing, so makeup packaging is becoming eco-friendly. Paper packaging is multiplying and made from renewable resources (recycled paper fiber and trees).

Let’s explore the different packaging papers for makeup and their types.

Paper Packaging Materials

The type of paper material that should be used and at what time is the project’s requirement. Following are the kinds of paper packaging materials print:

Coated Paper

Coated paper typically has a coating of clay or polymer on one or both sides. That’s why they are sealed. It allows the ink to stay at the top of the paper and restricts the amount that goes into it. The coating can be glossy, matte, dull, or cast-coated (high-gloss). The significant difference between these papers is the amount of coating applied.

Coated paper creates sharper and brighter images in case of printing purposes. It has better reflectivity even if you use dull-coated paper, and the print result would be much superior. These coated papers are printed at commercial companies, not paper mills.

Coated papers have been categorized in the following ways:

- Gloss-Coated Paper

This coated paper is shiny and exhibits high contrasts compared to uncoated paper. These papers are usually used for magazines where the colors of images require glam which is best-suited marketing material. However, this paper has a glare effect, making the text harder to read. This coated paper provides full-color images where the colors need to be shown popped. This paper provides a finish and a very professional look.

- Dull-Coated Paper

Dull-coated is used when text and images are equally important in the print job. The dull-coated paper provides good readability, whereas the coated paper makes the image appear smooth and high-quality.

- Matte-Coated Paper

Matte-coated paper is similar to dull-coated paper. This paper has less coating, and it feels lighter upon touching. This paper is less shiner than dull-coated paper. If we talk about the quality of this paper, then it comes among the least premium of the coated papers. Because of its properties, matte-coated paper is the least expensive one.

It provides a softer appearance than glossy paper. This coated sheet is the best to use to enhance visual designs with more subdued colors and without much glare.

- Cast-Coated Paper

High-gloss paper, also known as cast-coated paper, is a super-shiny paper. Due to its shiny surface, the reproduction of the image is superb and, therefore, ideal for die-cutting. Cast-coated paper is harder to work with. It is considered to be the most expensive among other coated papers.

This paper makes the color pop out, and the colors look vibrant. This paper is not a paper type but an extra coated paper applied to matte or gloss paper.

Wood-Free Paper

Wood-free paper is the new material keeping the urgent need for environment-friendly printing solutions in mind, and wood-free paper has increased in demand. It is also known as C2S/C1S. It is created from chemical pulp, not the typical way, i.e., mechanical pulp. Pulpwood is used to create a chemical pulp that is not considered wood.

Wood-free printing paper is rising due to its excellent content quality. Also, the easy application of easy pigment-based inks is the reason that wood-free paper is excelling.

There are two types of coating wood-free paper in the market. First is coated wood-free paper; it provides high ink gloss and protects from scratching and fingerprints from the surface. The glare of gloss-coated paper makes it difficult to read text easily. The second type is uncoated wood-free papers, which require extra drying time for ink. Uncoated papers are mainly used as protection and not for decoration or designs.

White Cardboard

White cardboard is a thick paper-coated paper board. This type of paper material is used in the graphic industry to make cartons, business cards, and picture albums. White cardboard is made using wood pulp as its raw material. Once the pattern is printed on white cardboard, it is difficult to interfere with external factors. This paper type can be stored for more periods than coated paper.

Wood pulp is higher in hardness as compared to the base paper. This paper is further processed to increase its hardness.

It is usually used in applications of postcards, invitation cards, product tags, and many other fields.

Kraft Paper

This paper is made from the chemical pulp produced during the kraft process. The pulp created by the kraft process is more substantial than the pulping process. Kraft pulp is darker as compared to wood pulp. However, it can be bleached to make a white pulp. A fully bleached kraft pulp is generally used to produce high-quality paper. Strength, whiteness, and resistance to yellowing the paper are fundamental; therefore, bleaching the dark pulp is required.

This paper is well-known among industrial and commercial uses because of its strength. You can use it as Kraft paper:

- Paint masking

- Floor covering

- Void fill

- Wrapping individual items

- Layering between pallets for protection

- Strength

Printing

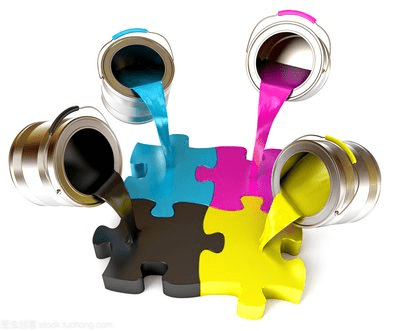

CMYK Process Color Printing

CMYK is a combination of four colors that provide the desired printing results, even if you want to match the previous project’s colors and match them to do a new project just like that. Process color applies C= cyan, M=magenta, Y=yellow, K= Key (the printer’s name for black), so black is the fourth color. You can create thousands of colors with these four colors.

CMYK inks are used in the pattern of dots that make similar pixels as shown in the digital image. This process of color printing is translated in percentages like C100%, M30%, Y0%, and K0% for blue color.

- Pros and Cons

- There are two standard color models, RGB (Red, Green, Blue) and CMYK (Cyan, Magenta, Yellow, Black). RGB is used for websites and digital communications, whereas CMYK is used for printing solutions. RGB is an additive model, and CYMK is a subtractive one. CMYK subtracts colors from the natural white light and turns them into dyes and pigments. Then printers make dot printing using these four colors. These dots are so together that it creates the required colors in high quality and contrast. RGB color ranges from 0-255, and CMYK ranges from 0-100%.

- If you see the difference between RGB and CMYK in color spaces, both have many color spaces with different gamuts. Adobe RGB offers a broader color spectrum, so if you want to print images, adobe RGB is better than CMYK. Check if the printer has been adapted for such color spaces or not.

- RGB and CMYK aren’t perfect because graphic designers need them to create unique logos and images. Both models are not able to reproduce all available colors in the spectrum.

- Make sure to convert your file before sending it to print into CMYK. Otherwise, the print colors won’t give the desired result.

Spot Color Printing

Spot colors are generally known as solid colors because there is no mixing of colors in this printing process. In this printing method, colors come as pre-mixed recipes. Colors and results may vary due to different printers, ink, and calibration settings. But one thing is sure you will be getting uniform and consistent colors always! They don’t vary from job to job and printer to printer.

- Pros and Cons

What is the difference between the two printing techniques? CMYK and spot color printing?

Use CMYK when:

- Jobs are not color critical, they involve more than three colors, and you need a low cost for printing. At the same time, spot printing consists of a printing tower for various colors, which makes the job more expensive.

- Printed pieces involve full-color images.

- When reproducing a print using the four colors.

Use Spot printing when:

- Job is color critical, like matching the colors of a brand’s logo

- Your printing involves less than four colors because fewer colors will be less costly with spot printing than CMYK.

- It is difficult for CMYK to replicate metallic and fluorescent colors; thus, spot printing becomes savage.

- You need to match solid colors from one piece to another, which can be achieved using spot colors to get greater consistency.

- Your work requires small font, reverse type, and fine lines of 0.5- or less. It is difficult for dots to do the task in such detail. Spot color printing works best for these tasks.

Common Types of Boxes for Cosmetic Packaging

Packaging is one and the most critical industry that works as the foundation or backbone of any company. For the cosmetic industry, packaging plays a vital role in grabbing customers; most importantly, the product’s safety is essential.

You can quickly draw your customers’ attention through catchy packaging box designs, sending messages by printing them, and controlling what they think of your product.

The packaging boxes are available in different shapes, sizes, materials, and colors. So, here is the list of packages for cosmetic packaging:

Folding Cartons

The first type of box in the packaging industry was folding cartons. At first, you only used them for expensive goods, but with time companies started to use them to secure their goods and to ship them safely to the consumers.

They are easy to use and seal. When they are not in use, you can easily fold them, save space, and reassemble them when needed. They are now being used to ship light products like shoes, canned goods, cosmetics, and clothes.

Rigid Boxes

Rigid boxes are much more durable and more substantial. They are made with sturdy materials. Some companies provide separate wrapping for rigid boxes of cute paper, fabric, or leather. In this way, the look of the package appeals to the consumer. Rigid boxes are used for high-end products like mobile phones and electronic products. It provides them extra support, and it carries heavy items well.

Corrugated Boxes

If the product is heavier than to carry by rigid box, then corrugated boxes work fine. They are made using corrugated cardboard. They maintain their sturdiness when piled with heavy packs. To prevent goods from damaging, these boxes are good to go. They are the best packaging boxes while shifting goods from the office or home.

Mailer Boxes

To mail smaller items, mailer boxes are specifically designed to serve such purposes. You can easily fit these boxes into the letterboxes. Therefore, making easier for deliveries easier. If you don’t receive the package, the delivery man leaves the box in the mailbox.

These boxes don’t require tape or any adhesive to close. The interlocking flapper and wings do the task well. The double side of the packages makes them durable and resistant to transport compared to other boxes.

Full Overlap Boxes

These boxes are tough and resilient. The boxes’ outer flaps overlap the entire package’s width, making it more robust and gripping the box nicely. Therefore, a space or surface is created where you can print the designs and images.

Full overlap boxes are used for heavy-duty products and heavy-duty purposes. The flaps of the packages extend outwards that completely overlap each other. This way, the box’s strength increases, making it ideal for storing or shipping heavy items.

Roll End Tuck Top Boxes

Roll-end tuck-top boxes don’t require glue. They can easily fold this box by putting it together. Such packages are helpful when you need to ship fresh products like cookies. They are best to use for retail products. Roll-end tuck-top boxes are customizable in various ways to appeal to customers. The top of the box can be customized transparently so that the product inside can be seen. For instance, to ship cakes, cookies, cupcakes, and other food items. Keeping the products in such a way will attract consumers’ attention, and therefore hygiene factor is also fulfilled.

Telescope Boxes

There are two pieces in telescope boxes that can be separable. The detachable parts are the base and the lid of the box. To present high-end products like technology, telescope boxes are used.

Collapsible Boxes

Collapsible boxes are handy boxes to ship products safely. These boxes are used for the product to stand out in the market. There are a variety of options you can choose from for these boxes. These boxes help you to save money on shipping.

Shoulder Boxes

Shoulder boxes are rigid boxes where the lid and the base do not meet. The middle section is all left in the box. Thus, it is known as the shoulder of the box. The product is stored in this spacious area. You can add images, printing, and different color contrasts to make the box look appealing.

Regular Slotted Container Boxes

The standard boxes used in the market are the regular slotted container boxes. The standard slotted container’s length is the same as the score to the edge. These boxes ship, pack, or deliver light and small items individually.

But the drawback of this box is that it does not offer customization since it is made equally and can only be customized for printing on the outer part.

Conclusion

Cosmetic packaging requires different types of packaging since there are a lot of shapes and products and the requirements of the products are different. Therefore, you should pick the packaging box you want accordingly. If you wish to ship the item or want packing for cosmetics, these boxes are being used to fit your requirements.

Also, the printing designs and options should be picked wisely for cosmetic products because the impression and look of the product will decide its sale and profit margins. So, make your product count using suitable printing options and packaging boxes.